Exact Welding Inspection Service for Metal Manufacture

Enhance Your Projects With Specialized Welding Services: Kinds and Advantages

In the globe of building and production, the importance of specialized welding services can not be overemphasized. From complex jobs that demand precision to massive industrial applications, the best welding strategy can make a significant distinction in the result of a project. As developments in technology remain to shape the welding sector, recognizing the kinds of specialized welding services offered and the benefits they provide is critical for remaining in advance in an open market. Whether it's the influence on building and construction projects, the applications in the manufacturing sector, or the advantages for numerous fields, discovering the world of specialized welding solutions unveils a world of possibilities that can elevate tasks to new heights.

Kinds Of Specialized Welding Solutions

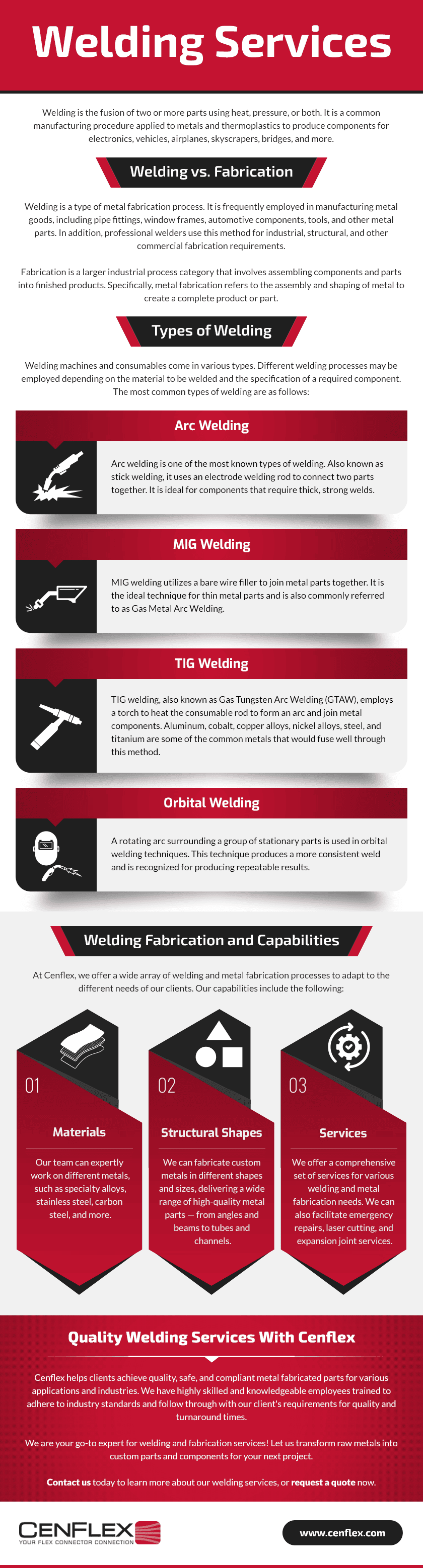

Specialized welding services include a variety of strategies tailored to specific industrial applications, including yet not restricted to TIG welding, MIG welding, and submerged arc welding. Tungsten Inert Gas (TIG) welding, recognized for its precision and tidy welds, is frequently made use of in sectors calling for top quality welds on products like stainless-steel and aluminum. Metal Inert Gas (MIG) welding, on the various other hand, is favored for its performance in handling thicker materials and high manufacturing prices, making it a prominent choice in auto and building and construction markets. Submerged Arc Welding (SAW) involves the formation of an arc in between a continuously fed cable and the workpiece, shielded by a layer of granular change. This approach is ideal for welding thick products in a solitary pass, commonly used in shipbuilding and infrastructure tasks.

Each of these specialized welding strategies uses special advantages tailored to particular project needs, highlighting the relevance of selecting the suitable technique based on product, thickness, and wanted weld features.

Benefits of Specialized Welding Solutions

The benefits of making use of specialized welding solutions in industrial applications are manifold, ranging from improved precision to increased performance in dealing with particular products and job requirements. One significant benefit of specialized welding solutions is the knowledge and experience that welders give the table. These specialists are learnt numerous specialized welding techniques, making sure that the welding procedure is brought out with the highest possible degree of ability and accuracy.

Effect on Building And Construction Projects

Drawing on the know-how of specialized welding solutions in commercial applications, the impact on building and construction tasks is substantial in terms of accuracy, efficiency, and total quality of welds. Building and construction projects count greatly on the structural stability of welded elements, making the precision offered by specialized welding vital. By making use of specialized welding services, building and construction groups can make certain that each weld meets the needed requirements, lowering the danger of architectural failings.

In addition, specialized welding strategies enhance effectiveness in building jobs by simplifying the welding procedure. With specialized devices and qualified experts, jobs that would certainly otherwise be taxing can be finished faster without jeopardizing high quality. This effectiveness not just speeds up task timelines however additionally decreases labor costs connected with welding.

In addition, the total top quality of welds in building and construction jobs is greatly boosted with specialized welding services. These solutions typically entail sophisticated welding technologies and extremely proficient welders who can create stronger, a lot more durable welds. The premium quality of welds achieved through specialized services adds to the durability and reliability of building and construction projects, guaranteeing that frameworks continue to be sound and risk-free for many years to find.

Applications in Manufacturing Industry

Within the production sector, the utilization of specialized welding solutions plays a critical duty in guaranteeing the integrity and effectiveness of production processes. Welding is a basic procedure in manufacturing, made use of in numerous applications such as joining metal elements, fabricating structures, and repairing equipment. Specialized welding techniques like TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, and robot welding are thoroughly utilized to satisfy the industry's certain demands.

One significant application of specialized welding in production remains in the auto market. Welding is pivotal in the setting up of automobile elements, making sure architectural stability and security. Additionally, the aerospace sector heavily relies upon specialized welding solutions to produce airplane elements with high precision and strength to withstand severe conditions.

Moreover, in the manufacturing of machinery and tools, specialized welding plays an important role in developing this page sturdy and reliable products. By utilizing sophisticated welding approaches, manufacturers can enhance product top quality, boost production efficiency, and eventually deliver exceptional products to the market - Welding Inspection Service. The specific and elaborate nature of specialized welding solutions makes them crucial in the manufacturing market's mission for development and quality

Advantages for Various Industries

With the crucial role that specialized welding solutions play in the manufacturing market, it is apparent that their benefits expand throughout various sectors, offering crucial advantages for different markets. Specialized welding solutions provide boosted accuracy and high quality control, guaranteeing that the last item satisfies rigorous market requirements. Additionally, specialized welding services can help markets meet details governing requirements, such as those in the oil and gas field or the nuclear industry, where safety and reliability are vital.

Verdict

In final thought, specialized welding services supply an array of benefits for construction jobs and the best site manufacturing sector. With different kinds of welding solutions offered, such as robotic welding and laser welding, organizations can boost the top quality and effectiveness of their jobs.

As innovations in technology proceed to shape the welding sector, comprehending the types of specialized welding solutions readily available and the advantages they offer is essential for staying in advance in an affordable market.Specialized welding services include an array of strategies tailored to details commercial applications, including however not limited to TIG welding, MIG welding, and immersed arc welding.Moreover, specialized welding solutions typically make use of sophisticated tools and technologies that are specifically made for intricate welding tasks. Specialized welding strategies like TIG (Tungsten Inert Gas) welding, MIG (Steel Inert Gas) welding, and robotic welding are thoroughly employed to meet the sector's details needs.